Polycarbonate Facades

The Facaplex Polycarbonate Façade is designed to facilitate high-quality cladding using hollow chamber polycarbonate sheets. This system utilizes our straightforward click mechanism, a minimal number of accessories, and the light weight of the panels.

Polycarbonate façades are equipped with UV-resistant coatings that protecting the building’s interior from harmful sun rays. Due to its lightweight design and simply construction system, the translucent building elements and accessories can be installed rapidly.

The alignment can be configured flexibly—whether vertical, horizontal.

By employing clip fasteners, the polycarbonate panels with a satin finish can be affixed to nearly all standard substructures for ventilated rainscreens.

Key Features of Polycarbonate Facades

- Light weight, but good thermal insulation

- Energy efficiency , U values low as 1.5 W/m²K to 0.75 W/m²K

- High load resistance

- Temperature resistant from -40° to +115°

- Easy and quick assembly

- High wind load resistance

- 3 meters unsupported spans can be realized

- thermal insulation properties are better with double wall structures

- Even transmission of light and eliminates glare

Specifications of Polycarbonate Facade

- Basic Product Specifications

| PRODUCT | Polycarbonate Panels 40mm | Polycarbonate Panels 50mm |

|---|---|---|

| Installation Module | 500mm width | 600mm with |

| Wall Structure | Multiwall | Multiwall |

| Wall Thickness | 40mm | 50mm |

| Max Length | Standard Up to 11.8 meters | Standard Up to 11.8 meters |

| U Value(W/m2K) | Minimum of 0.72 | Minimum of 0.72 |

| Light Transmission | Up to 30% | Up to 30% |

| Free Span Between Supports | 3 meters | 4 meters |

| 10 Year Warranty | Yes | Yes |

| Resistant To Fire | B | B |

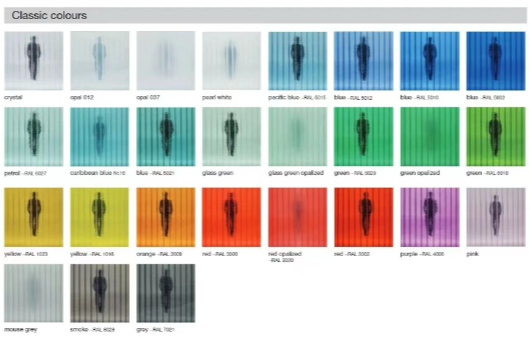

- Colorful Options

- Aluminum Options

Applications of Polycarbonate Facades

- Polycarbonate Facade Panels for Commercial Buildings

- Polycarbonate Facade for Hotels

- Polycarbonate Facade System for Modern Architecture

- Polycarbonate Facade for Schools and Universities

- Polycarbonate Facade for Hospitals

Services Offered

1. Vacuum thermoforming for polycarbonate sheets

DBI showcase the iconic columns on the main entry of W Brisbane, with a reflective ceiling and illumination to create a unique effect.

But polycarbonate materials convey the concept of a lightweight and light-transmitting design concept, they also retain the metallic texture of aluminum panels.

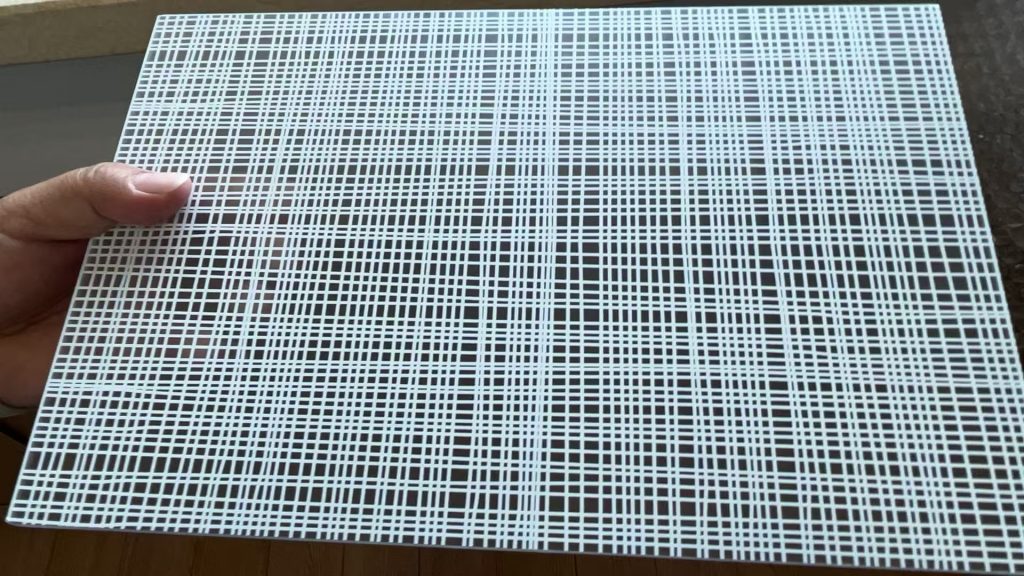

2. Silkscreen printing and digital printing on polycarbonate sheets

Why Choose Us

- Expertise in Manufacturing As a leading polycarbonate manufacturing and fabrication factory, we specialize in products and processing manufacture. We’re a group company specialized in construction field, we can produce a wide range of aluminum products tailored to your specific plastic sheets need.

- Design Capability Our team of experienced professionals is committed to transforming your ideas into innovative solutions. We work closely with clients to deliver customized designs that align with their vision and functional requirements.

- Quality Assurance We prioritize quality at every stage of production, from sourcing raw materials to final inspection, ensuring that our products exceed industry standards.

- Competitive Pricing Our efficient manufacturing processes and direct sourcing of materials enable us to offer competitive pricing without compromising on quality.

- Short Delivery Time

- Comprehensive Support From initial consultation to modular facade design, post-production transportation support, we provide comprehensive assistance throughout the entire project.

FAQ

Polycarbonate is a thermoplastic polymer recognized for its high impact resistance. It quickly gained popularity as safety glass and has been extensively used in curtain walls and facades. Its strength and versatility have seamlessly transitioned into architecture, where its translucency is ideal for various daylighting solutions, including curtain walling and wall light panels.

The choice of the right element depends on factors such as wind or snow load, required thermal properties or sound insulation properties, light transmission or even other project conditions.

The amount of light transmitted through translucent building elements can vary significantly based on several factors, including the material type, thickness, surface finish, and color of the element.

Material Type: Common translucent materials include glass, polycarbonate, acrylic, and fiberglass. Each material has different light transmission properties.

Polycarbonate: Typically transmits around 80-90% of light, depending on the specific product.

Thickness: Thicker materials generally reduce light transmission. As the thickness increases, the amount of light that can pass through decreases.

Surface Finish: Smooth surfaces tend to allow more light transmission compared to textured or frosted finishes, which diffuse light and may reduce overall transmission.

Color: Colored or tinted materials will absorb certain wavelengths of light, resulting in lower transmission rates.

Polycarbonate facades offer superior durability, thermal insulation, energy efficiency, and UV protection, making them a cost-effective and low-maintenance choice for modern buildings. They excel in areas requiring strength, impact resistance, and energy savings. Glass, on the other hand, provides unmatched aesthetic appeal and clarity with excellent natural light transmission but tends to be more fragile, costly, and less energy-efficient compared to polycarbonate.

Get Free Quote of Polycarbonate Facades

Related Products

Related News

Twinwall polycarbonate roofs are a versatile and durable solution for both residential and commercial projects. Known for their lightweight yet […]

Multi-Wall Polycarbonate is a versatile building material known for its unique combination of strength, light weight, and thermal efficiency. Unlike […]

Choosing the right roofing material can make a huge difference in both the durability and appearance of your outdoor or […]

Understanding Twinwall Polycarbonate Roof Features Polycarbonate pergola roof stands out for its lightweight yet strong structure. This material resists impacts […]

The main difference between twin wall polycarbonate and multiwall polycarbonate lies in the number of layers. Twin-wall polycarbonate features two […]

The difference between solid and multiwall polycarbonate sheets lies in their structure and performance. Solid polycarbonate looks like glass and […]

Selecting the right thickness for polycarbonate panels greatly impacts performance and longevity. People often compare polycarbonate versus glass, but polycarbonate […]

When choosing custom polycarbonate panels, buyers often look beyond basic durability. Key factors such as available sizes, cut-to-size options, thickness […]