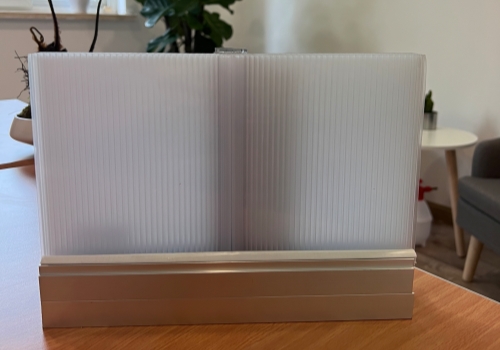

Facade offfers Polycarbonate Rainscreen Panels which a modern and innovative solution for building envelopes, combining durability, aesthetics, and functionality.

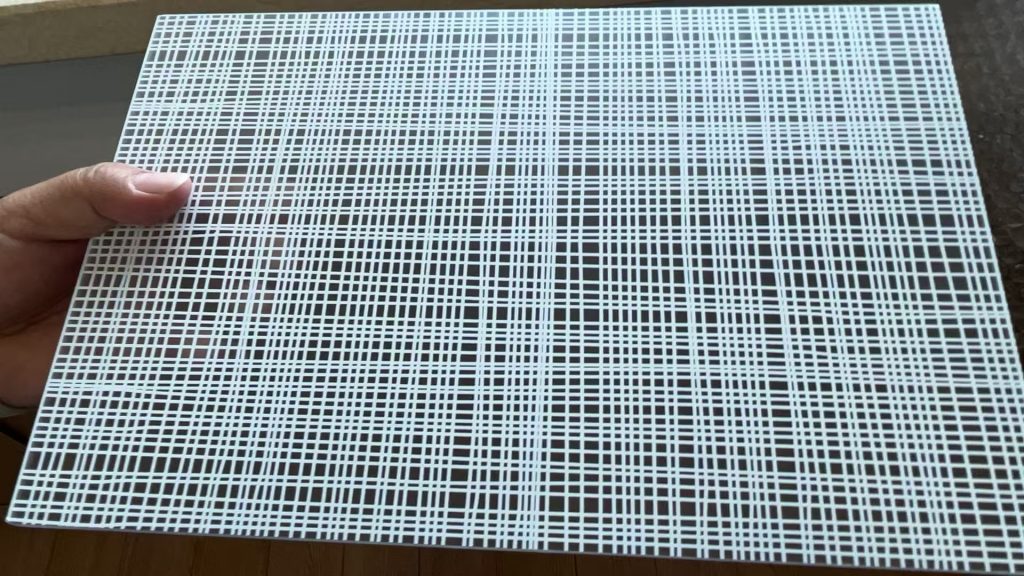

Polycarbonate rainscreen cladding is a lightweight, durable, and visually striking solution for modern building envelopes, combining functionality with aesthetic versatility.

Polycarbonate rainscreen Cladding System Features

- Translucent Daylighting: Allows natural light diffusion, improving interior brightness and energy efficiency.

- Lightweight & Easy to Install: Reduces labor and structural load requirements.

- Design Versatility: Available in various finishes and colors to suit diverse architectural styles.

- Weather Resistance: Performs exceptionally in harsh climates, including wind, rain, and temperature fluctuations.

- Sustainability: 100% recyclable material supports eco-friendly construction goals.

Key Beneftis of Polycarbonate Rainscreen Panels

- Lightweight Yet Durable

- Weather Resistance, UV coating

- Natural Light Diffusion

- Thermal Efficiency

- Design Versatility

Available in various colors, finishes, and thicknesses, enabling customization to fit diverse architectural designs. - Significant panel lengths (Up to 12.0m standard lengths, longer upon request)

- Reduce Installation Time, save labor costs

- Low Maintenance

- Enhanced Ventilation

Rainscreen systems create an air cavity behind the cladding, improving ventilation and moisture management. - Fire Performance

High-quality polycarbonate rainscreen can meet fire safety standards for building materials.

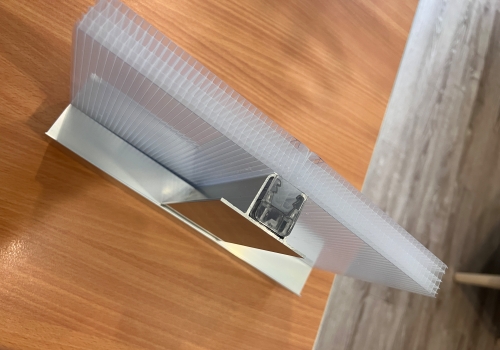

Specifications of Polycarbonate Rainscreen Cladding

| Material | Polycarbonate Panels |

|---|---|

| Thickness | polycarbonate solid sheet: 1mm - 30mm |

| Fire Resistance | UL94 V0, V2 |

| Temperature Adaptability | Long-term operating temperature: -40°C to +120°C. |

| Light Transmission | With varying colors, the light transmittance can reach up to 90%. |

| Impact Resistant | The impact strength is 250 times of glass and 30 times that of acrylic. |

| Weather Resistant | Co-extruded UV-resistant coating, ensuring excellent outdoor weather resistance. |

Explore Polycarbonate Rainscreen Cladding Solutions For Exterior Walls

Commercial Buildings

Modern office complexes, shopping centers, and hotels benefit from polycarbonate rainscreen cladding. The panels provide weather protection while enhancing the building’s exterior appearance with sleek, contemporary designs.Industrial Facilities

Factories, warehouses, and logistics centers require robust materials for exterior walls. Polycarbonate rainscreen panels offer impact resistance, long-term durability, and low maintenance, making them perfect for demanding industrial environments.Residential Projects

Contemporary homes and apartment complexes can incorporate polycarbonate rainscreen cladding to achieve a modern facade. Transparent or tinted panels allow natural light while protecting walls from rain and UV exposure.Public Infrastructure

Schools, hospitals, transportation hubs, and municipal buildings can utilize polycarbonate rainscreen systems to create durable, safe, and visually appealing exteriors that withstand heavy traffic and weather conditions.Recreational and Cultural Spaces

Museums, theaters, gyms, and sports facilities benefit from polycarbonate rainscreen’s aesthetic versatility. Panels can be customized in shape, size, and color to complement architectural design while providing weather protection.Retail and Hospitality Facades

Shops, restaurants, and cafes can use polycarbonate rainscreen cladding to create eye-catching exteriors. Lightweight and durable panels are easy to install and maintain, offering a practical solution for busy commercial areas.Green Buildings and Sustainable Design

Polycarbonate panels are recyclable and energy-efficient. They can be incorporated into environmentally conscious projects where insulation, light transmission, and durability are key factors.

Services Offered By Facaplex

We provide fabrication and thermoforming services for polycarbonate solid sheets, complemented by top-tier silkscreen printing. Our skilled team can create tailored shapes and designs, improving both the aesthetic and functional aspects of polycarbonate products for a wide range of applications.

1. Vacuum thermoforming for polycarbonate sheets

DBI showcase the iconic columns on the main entry of W Brisbane, with a reflective ceiling and illumination to create a unique effect.

But polycarbonate materials convey the concept of a lightweight and light-transmitting design concept, they also retain the metallic texture of aluminum panels.

2. Silkscreen printing and digital printing on polycarbonate sheets

Allows for personalized graphics, logos, and text tailored to specific preferences. Offers efficient printing for both small and large projects.

Louis Vuitton Maison Osaka Midosuji utilizes washi paper and glass curtain walls in its design. However, polycarbonate (PC) can achieve a similar effect when silk screen printing techniques, providing a lightweight and versatile alternative that captures the aesthetic qualities of traditional materials.

Why Choose Facaplex For Polycarbonate Rainscreen Cladding

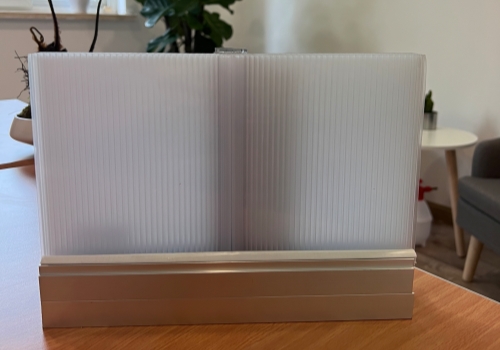

Facaplex Rainscreen wall systems with polycarbonate panels are lightweight and high impact resistant, ensuring easy installation without compromising structural integrity. The material is impact-resistant and weatherproof, providing long-term durability against harsh conditions. Its translucent properties allow for natural light diffusion, creating bright and energy-efficient interiors.

Polycarbonate rainscreen cladding materials are highly versatile, offering customization in colors, finishes, and thicknesses to suit diverse architectural styles. These panels contribute to sustainable building practices with recyclable components and energy-saving benefits.

Whether for commercial or residential applications, polycarbonate rainscreen systems deliver superior performance, aesthetics, and value, making them an ideal choice for contemporary construction projects.

- Expertise in Manufacturing

As a leading polycarbonate manufacturing and fabrication factory, we specialize in products and processing manufacture.

We’re a group company specialized in construction field, we can produce a wide range of aluminum products tailored to your specific plastic sheets need. - Design Capability

Our team of experienced professionals is committed to transforming your ideas into innovative solutions. We work closely with clients to deliver customized designs that align with their vision and functional requirements. - Quality Assurance

We prioritize quality at every stage of production, from sourcing raw materials to final inspection, ensuring that our products exceed industry standards. - Competitive Pricing

Our efficient manufacturing processes and direct sourcing of materials enable us to offer competitive pricing without compromising on quality. - Short Delivery Time

- Comprehensive Support

From initial consultation to modular facade design, post-production transportation support, we provide comprehensive assistance throughout the entire project.

FAQ

Polycarbonate cladding is a type of building material made from strong, lightweight polycarbonate sheets. It is often used for walls, roofs, and facades in homes, factories, and commercial buildings. This material is popular because it is durable, weather-resistant, and allows natural light to pass through. Polycarbonate cladding also provides good insulation, helping to keep buildings warm in winter and cool in summer. Its flexibility and strength make it a reliable choice for modern construction projects.

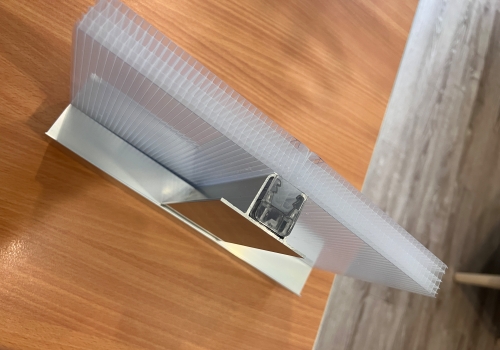

Polycarbonate is much lighter than materials like glass or metal, making it easier to handle and install. This can reduce labor costs and simplify the installation process.

Many polycarbonate cladding systems are pre-fabricated or come in panels that are ready to install, reducing on-site cutting and fabrication time.

While installation is typically straightforward, following the manufacturer’s guidelines and recommendations is essential for ensuring proper water drainage, ventilation, and thermal expansion.

Polycarbonate rainscreen cladding is a versatile option suitable for both new construction and retrofitting existing buildings. When planning installation, it’s essential to consider factors like structural requirements, aesthetics, insulation, and ventilation to ensure optimal performance and compliance with local building codes.

Polycarbonate cladding can be a cost-effective alternative to aluminum and glass, particularly in terms of material and installation costs. The final choice will depend on project-specific requirements, including aesthetics, durability, energy efficiency, and budget. It’s advisable to conduct a detailed cost analysis, including all associated aspects, to determine the most cost-effective solution for your specific project.

Polycarbonate cladding comes in different thicknesses, usually ranging from 4mm to 16mm. The right thickness depends on the application. Thinner sheets, like 4mm or 6mm, are suitable for small roofing panels or decorative walls. Thicker sheets, such as 10mm or 16mm, are used for larger roofs or areas that need extra strength. Choosing the correct thickness ensures safety, durability, and long-term performance for your building.

Polycarbonate rainscreen cladding is a versatile building material, but its suitability can depend on several factors:

1. Building Type: Polycarbonate cladding is often suitable for commercial, industrial, and residential buildings. However, for structures with specific historical or aesthetic requirements, other materials might be more appropriate.

2. Climate Considerations: Polycarbonate is typically weather-resistant, but in extremely hot or cold climates, special grades or treatments may be necessary to ensure performance and durability.

3. Fire Regulations: Some building codes have strict fire safety regulations. While polycarbonate has fire-retardant options, it’s essential to ensure that they meet local fire safety standards for the specific building type.

4. Structural Requirements: The weight and wind load capabilities of polycarbonate must be considered, especially for high-rise buildings or structures in high-wind areas.

5. Design Intent: If the goal is to maximize natural light while maintaining energy efficiency, polycarbonate can be a great choice.

6. Maintenance: Polycarbonate may require specific maintenance to avoid yellowing or degradation over time, which might influence its suitability depending on the building’s maintenance strategy.

Polycarbonate cladding is available in a variety of colors and finishes, allowing for flexibility in design and aesthetics. For example like Clear, Transparent, Frosted, Tinted, Opaque Colors and Custom Colors.

Finishes like Smooth Finish, Textured Finish, Matte Finish, Coated Finishes.

We offer polycarbonate sheets with a UV-resistant coating or treatment on one or both sides, which significantly enhances their ability to block harmful UV rays and prolongs their lifespan.

While polycarbonate provides decent thermal performance, it’s essential to consider other factors, such as the thickness of the panels, the configuration (e.g., clear vs. frosted), and the specific application to ensure that it meets the desired insulation and energy efficiency standards for your project.

Upgrade Your Cladding with Polycarbonate Rainscreen Panels

Explore the strength and design flexibility of polycarbonate raincreen cladding systems. Whether you’re enhancing daylight access or boosting building durability, our polycarbonate cladding panels offer the ideal exterior solution. Contact us now for custom specifications and a fast quote.