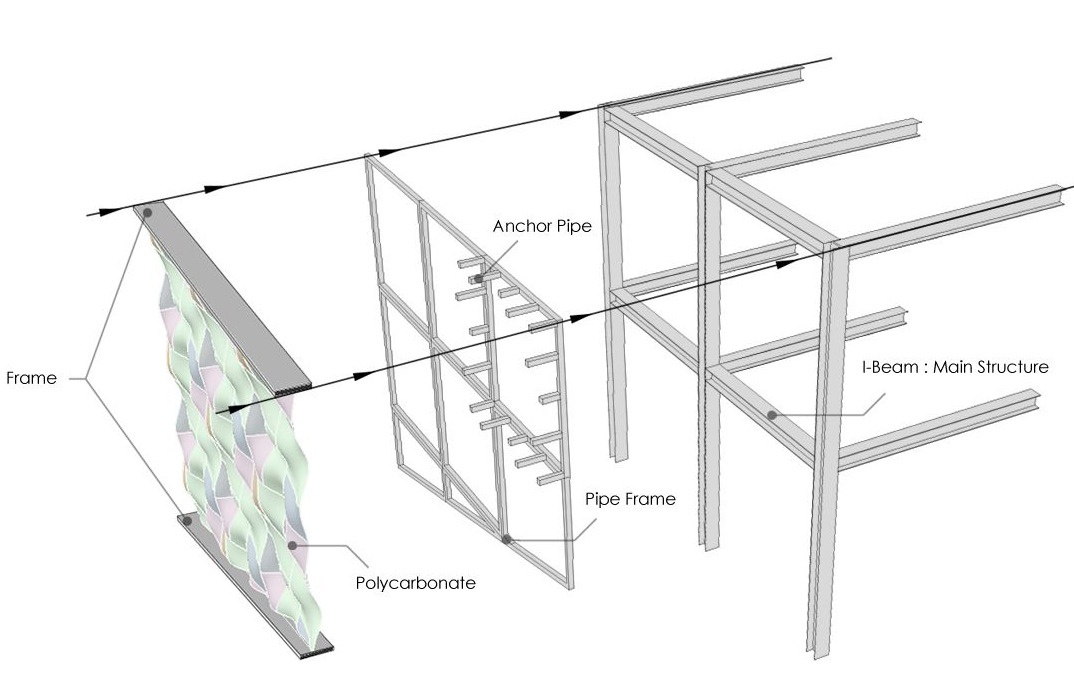

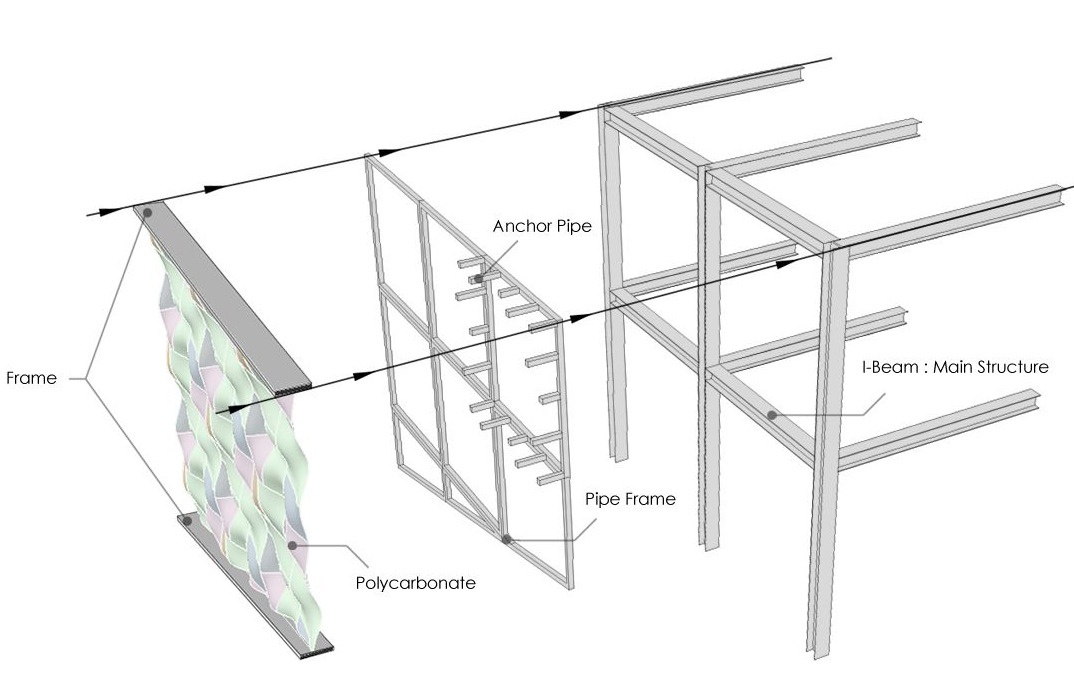

Polycarbonate Curtain Wall

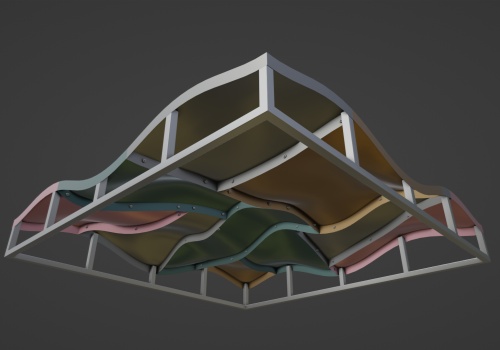

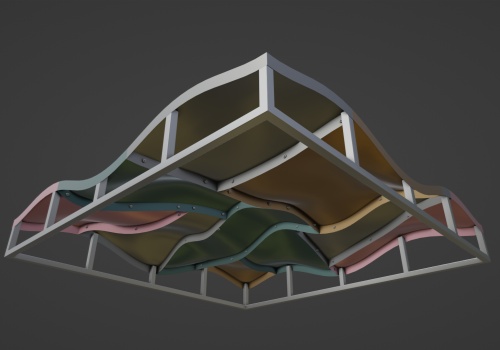

Polycarbonate Curtain Wall is a revolutionary Polycarbonate Architecture System in modern building design, offering innovative solutions that blend aesthetics with functionality.

Curtain Wall built with polycarbonate panel not only benefit from its remarkable durability and lightweight properties but also harness natural light, creating inviting and versatile spaces.

The polycarbonate façade serves as a striking feature, enhancing the visual appeal of the building while providing excellent thermal insulation and protection against the elements. Polycarbonate façade system makes an ideal choice for contemporary architectural endeavors.

Key Features of Polycarbonate Curtain Wall

- Aesthetic Appeal: Insulate buildings while allowing natural daylight, energy efficient wall solutions.

- Fire-rated Curtain Wall Materials: UL94 flame resistant – V0, V2

- Easy Installation and Maintenance: Polycarbonate material is lighter than traditional panels, making them easy to installation.

- Durability: UV-stable polycarbonate sheets, 15 years warranty for yellowing

- Design Flexibility: Customize polycarbonate panels colors, and aluminum frame structures

- Variety of Options: High-performance glazing solutions, Facaplex offers different types of polycarbonate panels with different transparencies and tints.

- System Benefits: Each component in the system can expand and contract at its own rate, it eliminates waves and deformation while maintaining the structural properties of the materials.

Specifications of Polycarbonate Sheets

| Material | Polycarbonate Panels |

|---|---|

| Thickness | polycarbonate solid sheet: 1mm - 30mm |

| Fire Resistance | UL94 V0, V2 |

| Temperature Adaptability | Long-term operating temperature: -40°C to +120°C. |

| Light Transmission | With varying colors, the light transmittance can reach up to 90%. |

| Impact Resistant | The impact strength is 250 times of glass and 30 times that of acrylic. |

| Weather Resistant | Co-extruded UV-resistant coating, ensuring excellent outdoor weather resistance. |

Applications of Polycarbonate Curtain Wall

- Commercial Buildings, large expanses of glass-like material that enhance visibility, light penetration, and modern aesthetics

- Hotels

- Public Safety Glazing

- Polycarbonate partition walls

Services Offered

We provide fabrication and thermoforming services for polycarbonate solid sheets, complemented by top-tier silkscreen printing. Our skilled team can create tailored shapes and designs, improving both the aesthetic and functional aspects of polycarbonate products for a wide range of applications.

1. Vacuum thermoforming for polycarbonate sheets

DBI showcase the iconic columns on the main entry of W Brisbane, with a reflective ceiling and illumination to create a unique effect.

But polycarbonate materials convey the concept of a lightweight and light-transmitting design concept, they also retain the metallic texture of aluminum panels.

2. Silkscreen printing and digital printing on polycarbonate sheets

Allows for personalized graphics, logos, and text tailored to specific preferences. Offers efficient printing for both small and large projects.

Louis Vuitton Maison Osaka Midosuji utilizes washi paper and glass curtain walls in its design. However, polycarbonate (PC) can achieve a similar effect when silk screen printing techniques, providing a lightweight and versatile alternative that captures the aesthetic qualities of traditional materials.

Why Choose Us

- Expertise in Manufacturing

As a leading polycarbonate manufacturing and fabrication factory, Facaplex specializes in products and processing manufacture.

We’re a group company specialized in construction field, we can produce a wide range of aluminum products tailored to your specific plastic sheets need. - Design Capability

Our team of experienced professionals is committed to transforming your ideas into innovative solutions. We work closely with clients to deliver customized designs that align with their vision and functional requirements. - Quality Assurance

We prioritize quality at every stage of production, from sourcing raw materials to final inspection, ensuring that our products exceed industry standards. - Competitive Pricing

Our efficient manufacturing processes and direct sourcing of materials enable us to offer competitive pricing without compromising on quality. - Short Delivery Time

- Comprehensive Support

From initial consultation to modular facade design, post-production transportation support, we provide comprehensive assistance throughout the entire project.

FAQ

What is a polycarbonate curtain wall system?

A polycarbonate curtain wall system is a modern facade solution using lightweight, durable polycarbonate panels. It provides excellent impact resistance, UV protection, and energy efficiency for commercial and residential buildings.

What are the advantages of polycarbonate curtain walls compared to glass curtain walls?

Polycarbonate curtain walls are lighter, shatterproof, easier to install, and more cost-effective than glass curtain walls. Multiwall panels also offer better thermal insulation.

Can polycarbonate curtain walls be used in high-rise buildings?

Yes, polycarbonate curtain walls can be applied in high-rise buildings, but fire-rated panels and proper structural support are required to comply with building codes.

How much does a polycarbonate curtain wall cost per square meter?

The cost depends on panel thickness, type (solid or multiwall), and installation complexity. Generally, polycarbonate curtain walls are cheaper than high-performance glass facades.

Are polycarbonate curtain walls weather-resistant?

Yes, high-quality UV-coated polycarbonate panels can withstand hail, strong winds, heavy rain, and temperature variations, making them ideal for harsh weather conditions.

What is the lifespan of a polycarbonate curtain wall?

With proper installation and maintenance, polycarbonate curtain walls can last 10–20 years. UV protection and regular cleaning help prevent discoloration and extend their life.

Can polycarbonate curtain walls be customized for different designs?

Yes, they can be customized in color, texture, opacity, or curvature, allowing architects to create unique building facades or skylights.

Are polycarbonate curtain walls fire-resistant?

Polycarbonate is combustible. For safety, fire-rated panels or coatings are recommended to meet commercial building fire safety standards.

How is a polycarbonate curtain wall installed properly?

Installation requires allowing for thermal expansion, using secure aluminum or steel framing, and sealing panels correctly to ensure durability and energy efficiency.

Where are polycarbonate curtain walls commonly used?

Polycarbonate curtain walls are popular for commercial facades, office buildings, skylights, stadiums, and structures needing lightweight, impact-resistant, and aesthetically flexible materials.

Get Free Quote of Polycarbonate Curtain Wall

Related Products

Related News

Twinwall polycarbonate roofs are a versatile and durable solution for both residential and commercial projects. Known for their lightweight yet […]

Multi-Wall Polycarbonate is a versatile building material known for its unique combination of strength, light weight, and thermal efficiency. Unlike […]

Choosing the right roofing material can make a huge difference in both the durability and appearance of your outdoor or […]

Understanding Twinwall Polycarbonate Roof Features Polycarbonate pergola roof stands out for its lightweight yet strong structure. This material resists impacts […]

The main difference between twin wall polycarbonate and multiwall polycarbonate lies in the number of layers. Twin-wall polycarbonate features two […]

The difference between solid and multiwall polycarbonate sheets lies in their structure and performance. Solid polycarbonate looks like glass and […]

Selecting the right thickness for polycarbonate panels greatly impacts performance and longevity. People often compare polycarbonate versus glass, but polycarbonate […]

When choosing custom polycarbonate panels, buyers often look beyond basic durability. Key factors such as available sizes, cut-to-size options, thickness […]